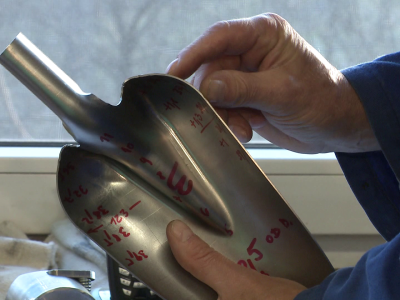

Pressing and machine shop

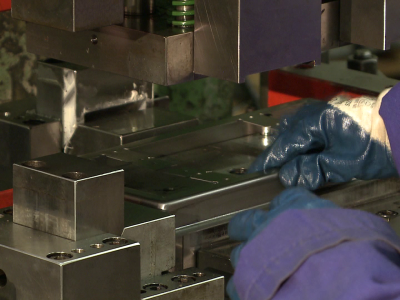

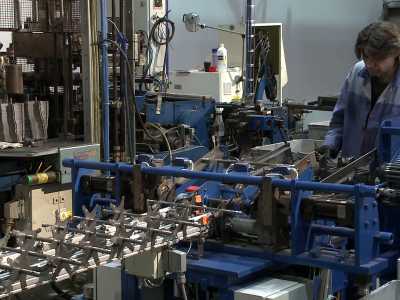

It uses the technology of hydraulic and eccentric presses with a tonnage up to 315 tons for pressing metal. For production in large series we use four automatic pressing lines with a speed of 80 pieces per minute and tonnage of 150-315 tons that manage to press metal sheets and coils 0.4 -6 mm thick and corss-section up to 1500 sq.mm of commercial and carbon steel, including non-ferrous metals.

In addition, the pressing shop involves 30 hydraulic and eccentric presses with a tonnage ranging from 5 to 150 tons manually and semi-automatically operated. Due to the fact we are able to manage orders from 1,000 to 50,000 pcs/year.

Within the machine shop we provide production by split and bent blanks of logs, bars and tubes up to 50mm diameter in grade of structural and carbon steel.

- 7 automated press lines - WEINGARDEN, ERFURT, RÖSLER, SMERAL, HEILBRON

- Laser cutting of smaller series in the thickness off 20 mm - TRUMPF 3030

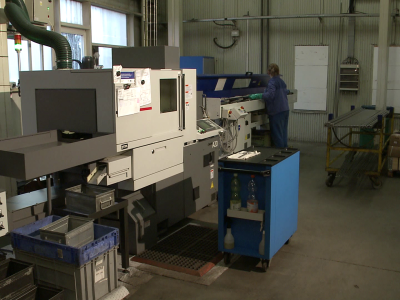

- Splitting of logs, hexagons and pipes on automatic machines REMS, SINICO

- CNC metal machining - turning, milling, drilling, threading of squares / spindles up to 38 mm - CNC CITIZEN CINCOM L20 and L32

- 3D wire bending machines MACSOFT, BRUGER, BIHLER, E-FLEX

- Processing of ordinary and carbon steel, stainless steel, non-ferrous metals.