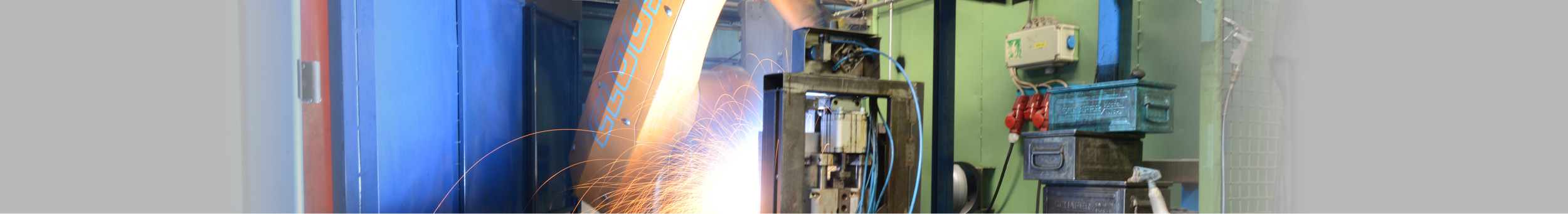

Welding and grinding shop

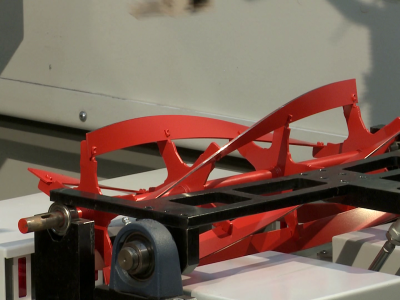

Moldings and handles workpieces weighing up to 15 kg.

There are vending and semi-automatic MIG / MAG welding machines with linear and circular trajectories.

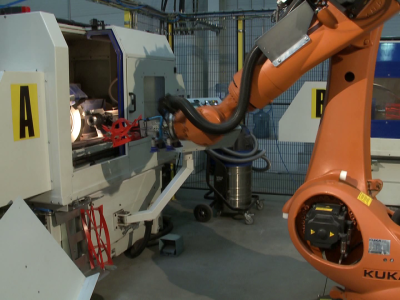

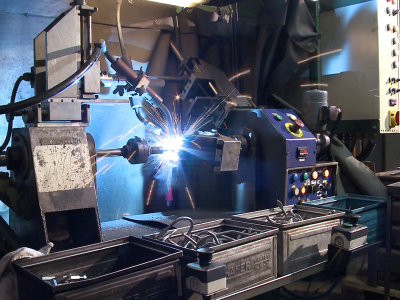

Welding robots

- KUKA – newly fitted EWM PHENIX 452 source, welding of carbon steel, stainless steel and AL.

- CLOOS – 2 robots equipped with a CLOOS source and a positioning table.

- MOTOMAN – equipped with a SKS source and a positioning table, welding of carbon steel, stainless steel and AL.

25 semi-automatic welding workplaces

- Staffed by EWM, CLOOS.

- Spot resistance welding.

- Merkle welding sources Welding of carbon steel, stainless steel and aluminum.

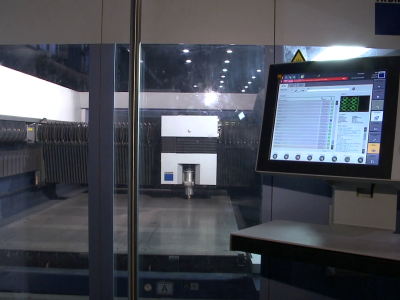

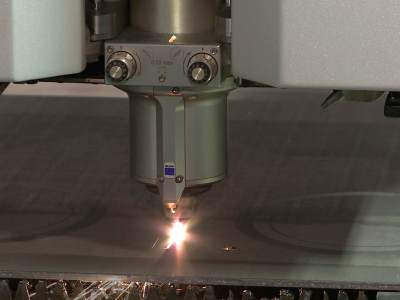

- Laser cutting with a TRULASER 3030 (L20).

- Sheet size 1500 × 3000 mm.

Max. material thickness

- AL – 8 mm

- Stainless steel – 12 mm

- Carbon steel – 20 mm

- New robotized KUKA workplace for round grinding.

- Two-shift operation of the welding shop ensures 6 adjusters, 25 welders, and the welding shop foreman.

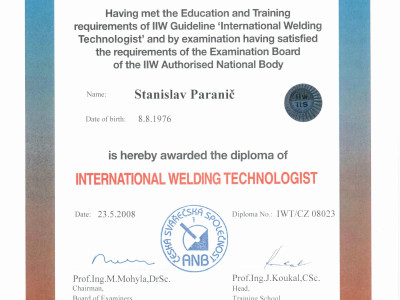

- A welding technologist IWT certified with the authority of a welding technician CWS ANB.

- A continuous visual inspection of welds DW-2 metallographic tests.

- Automatic grinders, round and flat grinding.